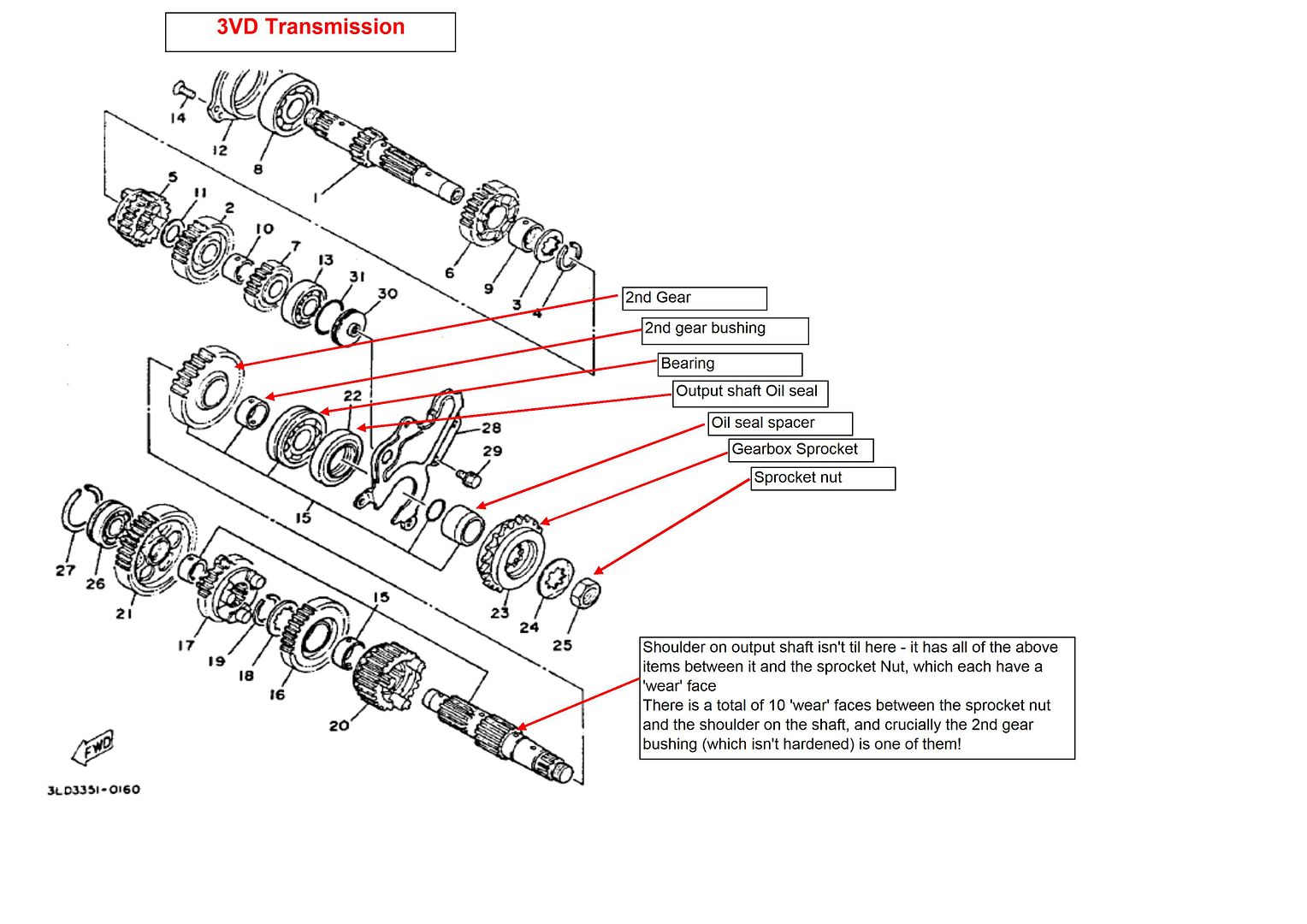

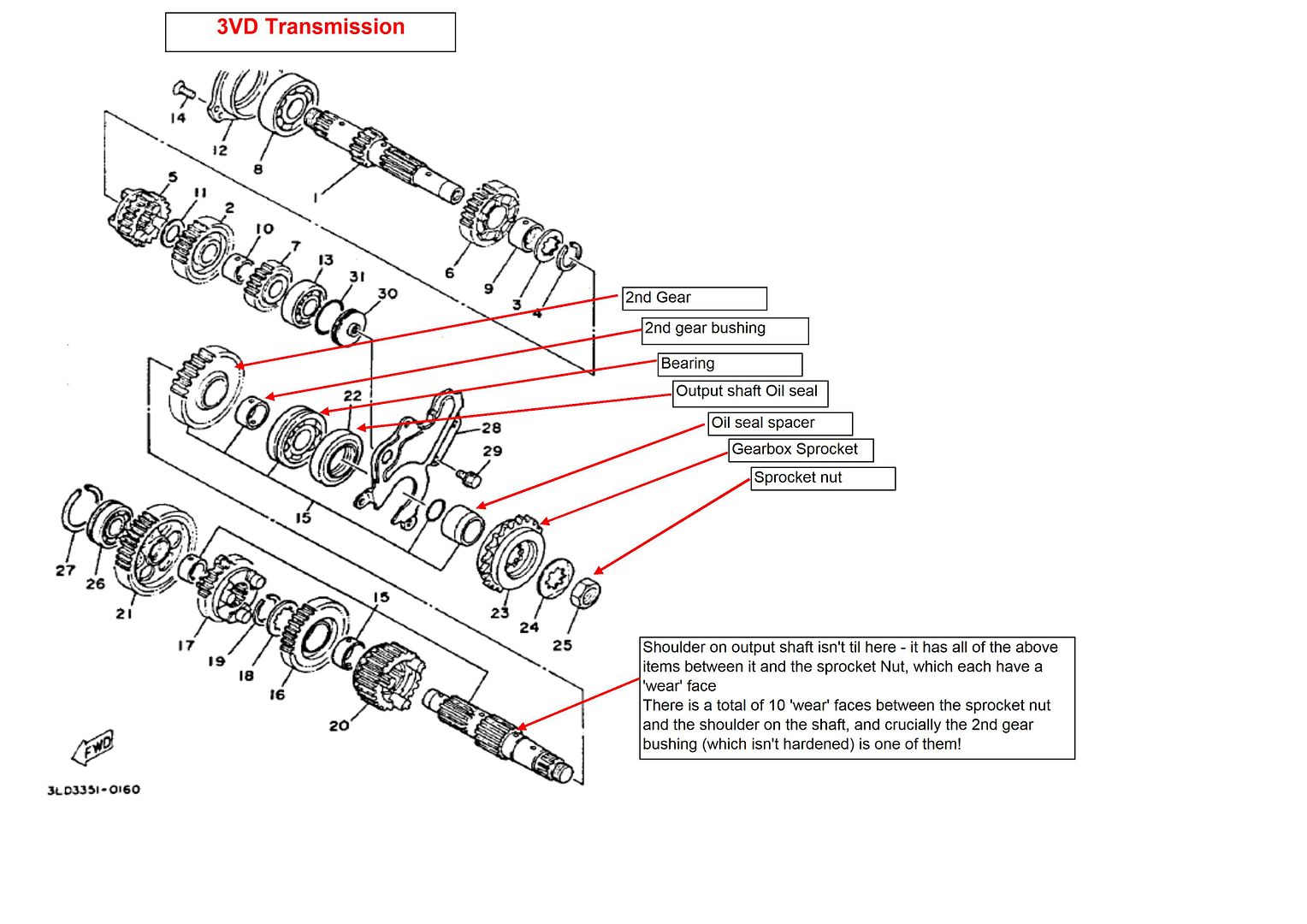

look at the microfiche below of the TDM 3VD transmission

You see the 2nd gear bushing (part of group of items labeled as '15'

when you torque up the nut, it clamps against the sprocket, which clamps against the oil seal spacer, which clamps against the bearing inner race, which clamps against the second gear bushing, which clamps against the shoulder on the outputshaft and hence everything is clamped up tight

The constant back and forth shocks as lemonentrails quite rightly points out from the acceleration and deceleration, makes the sprocket rock back and forth. Where lemonentrials is wrong is assuming this wear takes place in the splines and loosens the nut

This is the second gear bushing from my DRZ400S, which has the same transmission set up, and also suffers from loosening front sprockets. Mine came loose twice, despite being torqued to the correct figure of 70Nm

See that groove on the outer face, thats where the inner race of the bearing clamps against it, and when tight, spins with the bearing and shaft.

As the bearing is harder than the bushing, the bushing wears, and hence causes the loss of clamping press without the nut ever actually moving.

Now, it may be the second gear bushing that wears on the TDM, or it maybe something else, as I have not examined the parts from a bike on which the sprocket has been loose, but the key to stopping the wear, and hence stopping the loose sprocket is to stop the sprocket from rocking back and forth.

The pressure applied by the sprocket nut is not enough to do this, else they wouldn't come 'loose'. This is why you need the loctite on the splines, to prevent this movement.

Ordinary blue thread lock, or Loctite Stud'n'Bearing (red) is not strong enough (I know, it failed to do the job twice on my DRZ) , but Locitie 638 most certainly is

Edited by GuyGraham, 05 July 2008 - 05:40 pm.