Modding A 900 Exhaust.

#21

Posted 22 September 2009 - 10:49 am

#22

Posted 23 September 2009 - 08:50 pm

If you went the whole hog and ran a good drill all the way down the outlet pipe (oh Matron) and drilled in to the back plate nearest the connecting pipe what would happen

A chopper sound?

A f**ked up engine?

A knock on the door from the Cops?

No money?

How stuck is the pipe? could you drag the lot out with a bit of movement and a caveman attack.

#23

Posted 24 September 2009 - 09:34 am

A chopper sound?

A f**ked up engine?

A knock on the door from the Cops?

No money?

How stuck is the pipe? could you drag the lot out with a bit of movement and a caveman attack.

A couple of posts back I linked to the French TDM forum, and if you have a browse around there you will find that this is what gets done to the 850 exhausts (also get done to the FJR's). Drill around the exit pipe, break/grind the metal between the drilled holes, to isolate the exit pipe. THEN. Using a piece of sharpened re'bar (concrete steel reinforcement bar, or steel rod) you reach in and cold chisel the welds on the inner baffle. Yes, the caveman attack. They then place a flanged piece of pipe over the new rough cut hole to clean things up.

#24

Posted 24 September 2009 - 10:38 am

And for the 900 you DO NOT drag the whole pipe out, just cut off the bit on the "outside"

Correct?

#25

Posted 24 September 2009 - 11:51 am

Correct?

Yes, correct. For the 900. That pipe is welded solid, where it passes into the middle chamber, mine hasn't budged in about 700kms since the mod... I don't expect it ever will move.

Cut off the tip so that the weld stays with the tip, then reach into the muffler and make another cut... then withdraw that smaller piece to bypass the middle chamber.

#26

Posted 24 September 2009 - 12:10 pm

Maybe you knew that the inside pipe is stuck on the other side but if I look inside I can't see where, somehow is stuck.

Your bike is from 2008 , isn'it?

Perhaps the exhaust pipes in 2005 of mine are different and they change country by country.

Here in Italy we have RN11 euro2 pollution law ,and RN18 euro3 pollution law.

Anyway inside my Can I don't see anything to support the pipe , except on the outside weld

Cheers, Marco

Sorry Marco,

I missed your post earlier.

I really can not comment on other models, mine is 2009, sorry I can't offer more fact. But my guess is they would be the constructed the same because, the Euro market is the biggest for the TDM and, Yamaha is very unlikely to make a specific muffler for Australia... they only sell 12-24 a year. (Don't quote me on any of this!)

Below is a photo of the stamping on the left muffler of my 2009.

Looking, with a torch, from the outside I can see no weld either... but that piece of pipe is fixed in there SOLID, I did try moving it.

Edited by AzzA, 24 September 2009 - 12:15 pm.

#27

Posted 24 September 2009 - 12:50 pm

First a reference to what we're looking at:

Now for some cutting, yes, the red lines:

A final result, and if you want more gas out faster and louder:

#28

Posted 24 September 2009 - 01:07 pm

The first cut is (always the deepest) going to be the hardest, and you are aiming to be just behind the weld... don't be too keen, you can always grind off any little bits you miss:

The weld metal is harder than the rest of the pipe, go slow and easy and you wont chew as many discs.

Once you have the weld cleared, you reach into the pipe again and cut inside the muffler... don't go too far in; you can always cut more later:

Try to make both second cuts the same, to make each muffler match.

Edited by AzzA, 24 September 2009 - 01:14 pm.

#29

Posted 24 September 2009 - 01:22 pm

With this & the screen mod's - looks like I might have a busy weekend ;-)

-----

Fuel Pipes

Givi Top Box

Renthal 758's

Grip Puppies

MRA Bubble

Dip & Hi HIDs

To-Do:

LED DRLs

Loobman

Powercoat Wheels

Hand Guards

-----

...

... ...

... ...

... ...

...

#30

Posted 24 September 2009 - 01:24 pm

Mixture (CO): to reduce excess unburned fuel.

"air cut-off valve" or the "reed valve": to reduce available O2 in the exhaust.

Even with expensive after-market exhausts you may want to do these, it will depend on your tuning/bike and how you ride it.

Edit: You may notice the idle drop a bit, just wind up the "idle adjustment screw" (under the frame near your right leg calf)... wait until the engine is fully warm first. 1100-1200 RPM is the target.

Edited by AzzA, 24 September 2009 - 01:28 pm.

#31

Posted 24 September 2009 - 01:30 pm

Mixture (CO): to reduce excess unburned fuel.

"air cut-off valve" or the "reed valve": to reduce available O2 in the exhaust.

Even with expensive after-market exhausts you may want to do these, it will depend on your tuning/bike and how you ride it.

Edit: You may notice the idle drop a bit, just wind up the "idle adjustment screw" (under the frame near your right leg calf)... wait until the engine is fully warm first. 1100-1200 RPM is the target.

When you say "air cut-off valve" do you mean the airbox mod?

-----

Fuel Pipes

Givi Top Box

Renthal 758's

Grip Puppies

MRA Bubble

Dip & Hi HIDs

To-Do:

LED DRLs

Loobman

Powercoat Wheels

Hand Guards

-----

...

... ...

... ...

... ...

...

#32

Posted 24 September 2009 - 01:35 pm

With this & the screen mod's - looks like I might have a busy weekend ;-)

You're welcome.

Template: the chuck will adjust in/out on most of these tools, some come with removable collars behind the chuck too, fiddle around and you'll work something out. It needn't be too perfect, and you can always even things up by some fine grinding after the cutting.

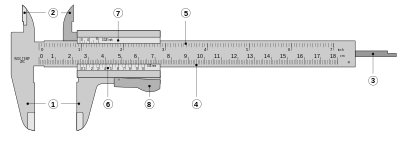

You can get cheap plastic Vernier Calipers at most budget tool outlets, ones like these have a depth gauge wire out the tail. (3) in this picture.

Edited by AzzA, 24 September 2009 - 01:36 pm.

#33

Posted 24 September 2009 - 01:44 pm

Dont know if i missed it, but does it more than make a ruff sound. Are you getting more hp out of it? more mpg? or some other good stuff?

Tdm 900 and Labrador.

Can it get any better.

Dont think so.

#34

Posted 24 September 2009 - 01:49 pm

Under the red "6" in Celtikbikers photo, from his great service "how to", there is a rubber hose.

Disconnect this hose, block it with a marble or something, and reconnect it.

You can see the feeder hole in the lower left, inside the airbox. You don't have to remove the airbox, or even open it, just lift the tank.

This hose feeds filtered air to the "air cut-off valve", then to the "reed valve", and finally into the exhaust ports.

This air mixes with the exhaust gasses and allows any unburned fuel to burn.

Block it and it's less likely to burn, hence less "pop".

You can take the marble out for your MOT, but if the test is only done at idle you could probably leave it in (don't quote me on that; I have no idea how tight the regulations are there).

Only bother doing this if pop is an issue... does kinda add character to a bike.

#35

Posted 24 September 2009 - 01:58 pm

I'll have a go at the weekend (weather permitting) and put up some pic's of progress.

Really want to get Beuwolfs, but this reads like a damm good alternative pending cash flow ;-)

-----

Fuel Pipes

Givi Top Box

Renthal 758's

Grip Puppies

MRA Bubble

Dip & Hi HIDs

To-Do:

LED DRLs

Loobman

Powercoat Wheels

Hand Guards

-----

...

... ...

... ...

... ...

...

#36

Posted 24 September 2009 - 02:19 pm

Dont know if i missed it, but does it more than make a ruff sound. Are you getting more hp out of it? more mpg? or some other good stuff?

Sound: a very subjective thing to describe, and equally as hard to reproduce with the media available to me.

- is louder than stock,

- with a definite sharp bark under throttle when engine load is low,

- a more rounded "womp-womp" sound under load from low RPM,

- has the unmistakeable 270deg (V) twin sound... bit like a hotted up Triumph 270deg twin or mild harley,

- sound is mostly left behind at cruise, until the throttle is opened up.

Don't know about HP, but torque is much better from lower down in the RPM... I find myself riding around town at about 750-1000 RPM less, 2-3ish not 3-4ish, the difference of an earlier gear change.

Same mileage.

I have noticed that holding a steady speed at cruise is easier. Possibly from a bit more torque, possibly the aural feedback, likely a combination of the two.

It's great to hear the rev's (via the exhaust not the cam-chain etc), when coming out of corners at speed or when overtaking cars.

Yamaha not Singer or Brother, after all.

#37

Posted 24 September 2009 - 04:29 pm

since there's gap.. would water goes into exhaust and stays inside at last compartment ? unlikely river crossing but due to heavy rain...

#38

Posted 24 September 2009 - 07:27 pm

It's great to hear the rev's (via the exhaust not the cam-chain etc), when coming out of corners at speed or when overtaking cars.

Yamaha not Singer or Brother, after all.

Thank you very much Azza !

Sound is the thing I am missing. I think the exhaust is stainless steel, so the cutting will probably not make it rust.

I am thinking about about buying an old TDM900 exhaust to modify to keep my first one untouched.

#39

Posted 25 September 2009 - 01:52 am

since there's gap.. would water goes into exhaust and stays inside at last compartment ? unlikely river crossing but due to heavy rain...

Due to the use of catalytic converters these mufflers are designed to let water out, how much they can cope with I can't say, but if you look at the rear lower end you will see a hole... you will see another in the band of the heat deflector, just behind the cat's... keeping the holes clear and clean, with wire, should keep things OK.

If storing outside in horizontal rains, or when pressure washing, get some plugs. Like these:

Any dirt bike shop will have them, most other bike shops too.

#40

Posted 25 September 2009 - 02:05 am

The original pipe is 25mm. The red lines would be the new exit at ~38mm, it would be flanged and mounted by rivets (green).

I expect the larger exit diameter would allow lower frequencies out (sound wise), and also more free flowing gasses... maybe a bit more usable torque... but just guesses so far.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users